ABOUT FUSAPIPE

Polypropylene Random is an evolutionary leap in plastic pipe technology and has numerous advantages over metallic pipes and fittings:

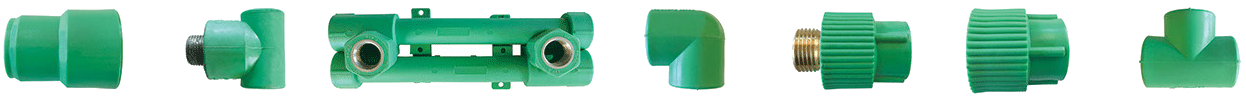

- Wide variety of components to cover all your fluid supply needs.

- Mechanical strength and durability.

- Corrosion is non-existent.

- Far greater heat retention.

- Very high resistance to condensation.

- High resistance to most chemicals.

- Hygienically sound with no adverse effects on portable water.

- Quiet transfer of liquids in the system.

- Total flow during entire life span of the product.

- Ideal for hot and cold water installations giving you a wider range of temperature application.

- Highly resistant to chemical corrosion due to being a bad conductor of electricity.

- Excellent flow performance properties. Better flow rate than copper.

- Easy and reliable installation technique.

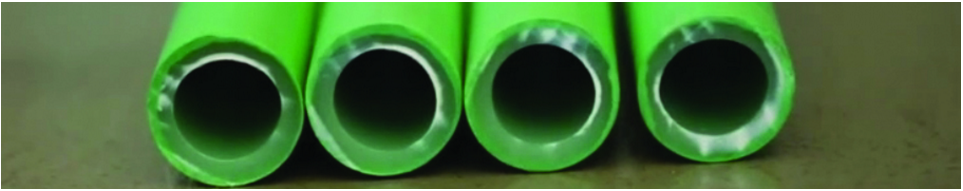

- Perfect internal surface.

- The most reliable piping system available. Long and trouble free service life.

- Highly competitive pricing. Excellent price to benefit ratio.

BENEFITS & ADVANTAGES

-

One complete system

One simple system for transferring hot and cold water in buildings of any size.

-

Guaranteed for 30 years

We guarantee our piping system for 30 years provided it’s installed by a qualified plumber trained in the installation of our products. T&C’s apply.

-

Faster and easier to install

Pipe fittings are joined using a fusion welding process, which is much quicker and reduces labour costs.

-

More reliable long term

Fusion welded joints form a consistent, permanent, lifelong leak proof bond.

-

More cost effective

As much as 30% less expensive than copper and can save you up to 20% on plumbing materials. Plus, no more copper theft. Excellent price/ benefit ratio.

-

SABS approved

The only locally manufactured SABS SANS 15874 approved poly pipe system for hot and cold water.

-

Resistant to corrosion and encrustation build up

Chemical resistant, non-toxic alternative with zero health risks due to it being a poor conductor of electricity.

-

More energy efficient

Provides evident water and energy savings compared to metal piping because of reduced heat loss and piping condensation.

-

Nearly frictionless flow

Produces better flow rates than copper piping and makes less noise because liquids are transferred quietly in the system.

-

Low maintenance

Since corrosion and leaks are non-existent the system doesn’t require constant maintenance, even after years of use, and large-scale water damage is less likely to occur. Expected service life of the pipes and fittings can reach up to 100 years depending on the installed system pressure, applied temperature and pressure changes. Pipes & fittings are designed to withstand constant temperatures up to 70˚C and rises up to 100˚C over practical periods of time.

-

Always available

Being locally manufactured our pipes and fittings are readily available and can be delivered on site in a timely manner, preventing project delays.

-

Eco-friendly

PP-R can be recycled and used in a variety of applications throughout it’s lifespan.

APPLICATIONS

Hot and cold potable water pipe delivery networks in virtually all buildings including residential & office buildings, high-rise buildings and functional buildings such as schools, hospitals, hotels and stadiums.

- Boilers and accumulator connections.

- Liquid distribution in industrial plants.

- Compressed air circuits.

- Piping layouts for swimming pools and solar energy installations. Should the pipe be used on solar systems, the pipe work from the solar geyser should be a metal pipe for at least 3 meters before using our pipe for the rest of the installation as per plumbing regulations.

- It can be used for new installations as well as for repair work.

- Plumbers.

- Construction.

- Air conditioning installers.

- Pool installers.

- Solar installers.

INSTALLATION

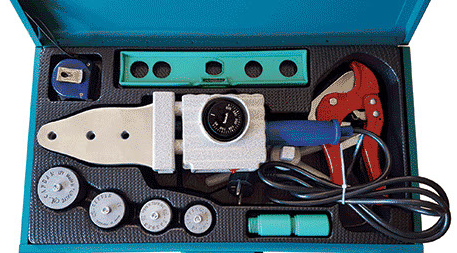

The pipe and fittings are joined by use of a Plastic Pipe Heat Fusion Machine.This machine is portable so it’s easy to use on-site.

The kit includes the fusion machine, a pipe cutter and welding sockets ranging from 20mm - 40mm.

The sockets are then attached to the fusion machine. Once the machine is powered and heated up it is ready for use.

The pipe and fitting is inserted over and into the relevant sockets.

Within just a couple of seconds the pipe and fitting will be in a more flexible state, and can be removed from the socket and joined together by fusion.

This process physically melts the two parts together making sure it’s sealed permanently.

For the correct insert depth and heating times please refer to our technical catalogue.

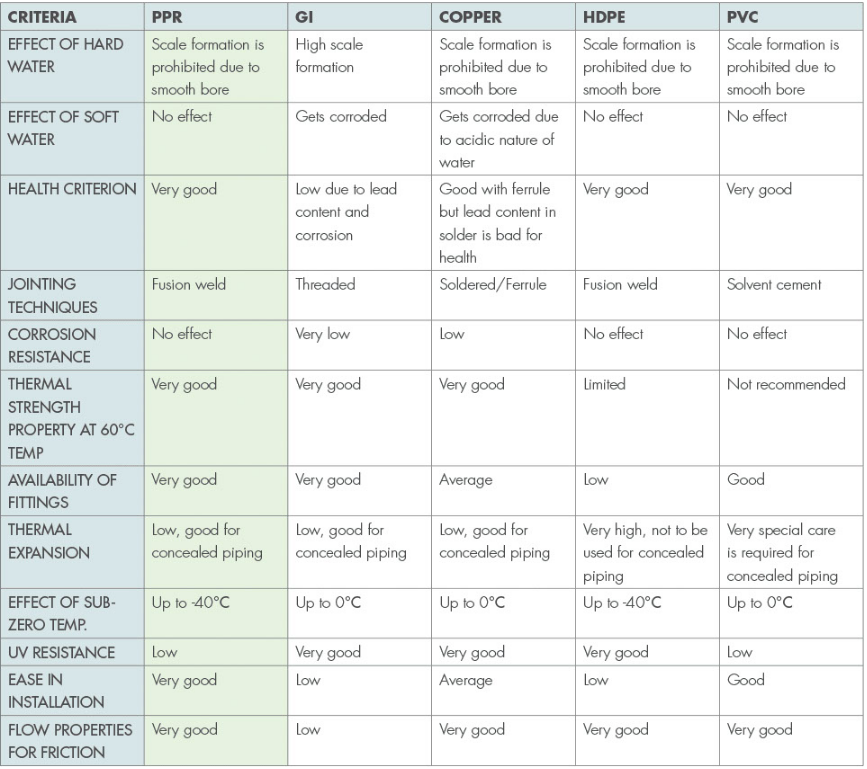

PIPE MATERIALS COMPARISON CHART